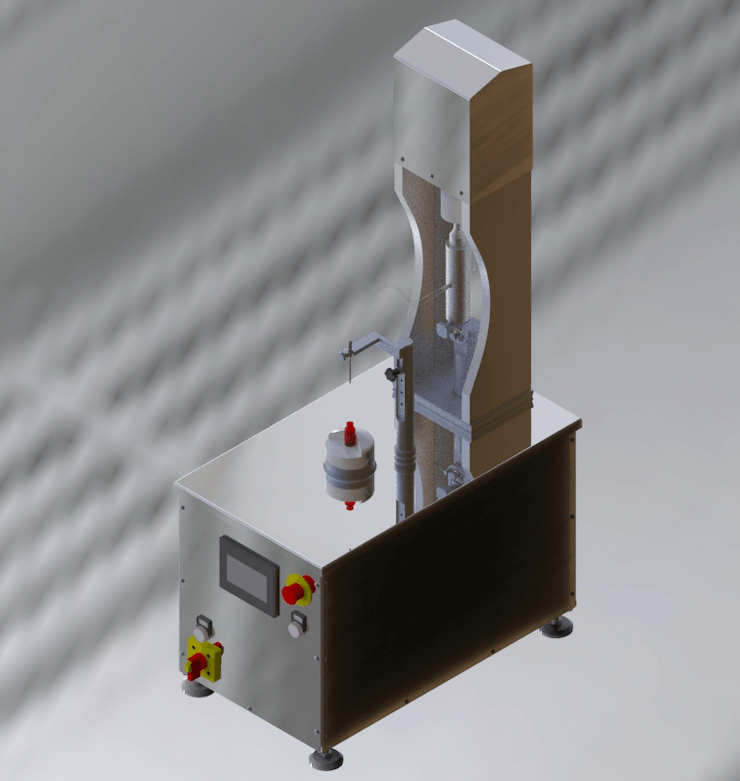

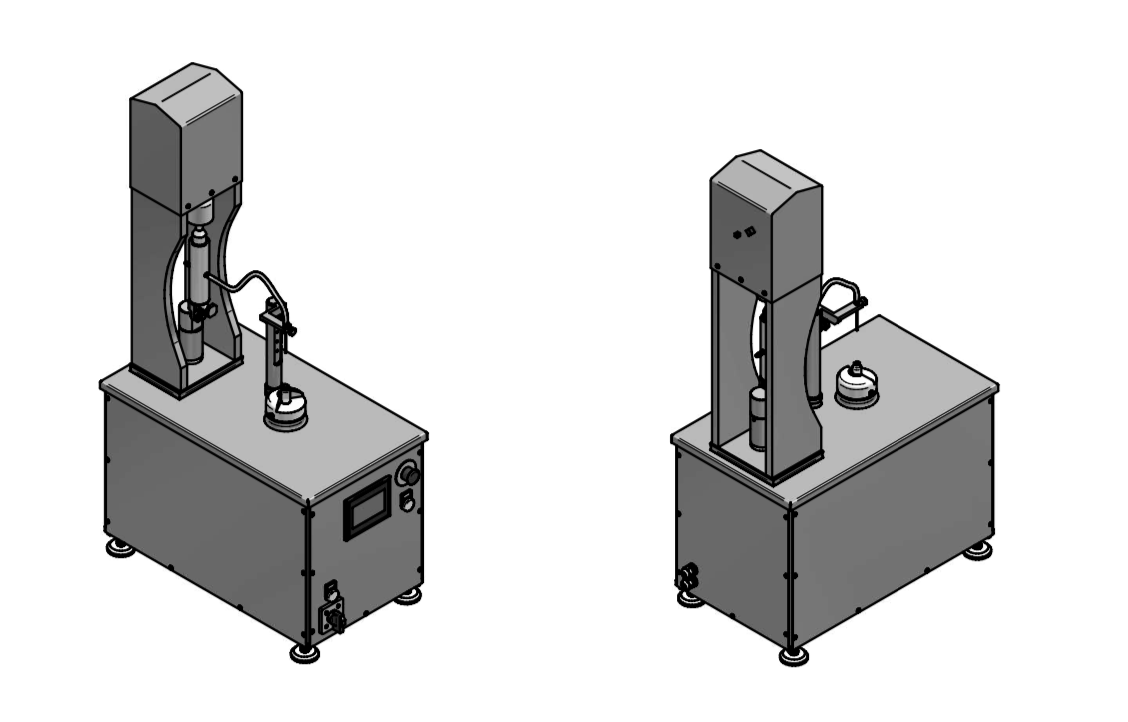

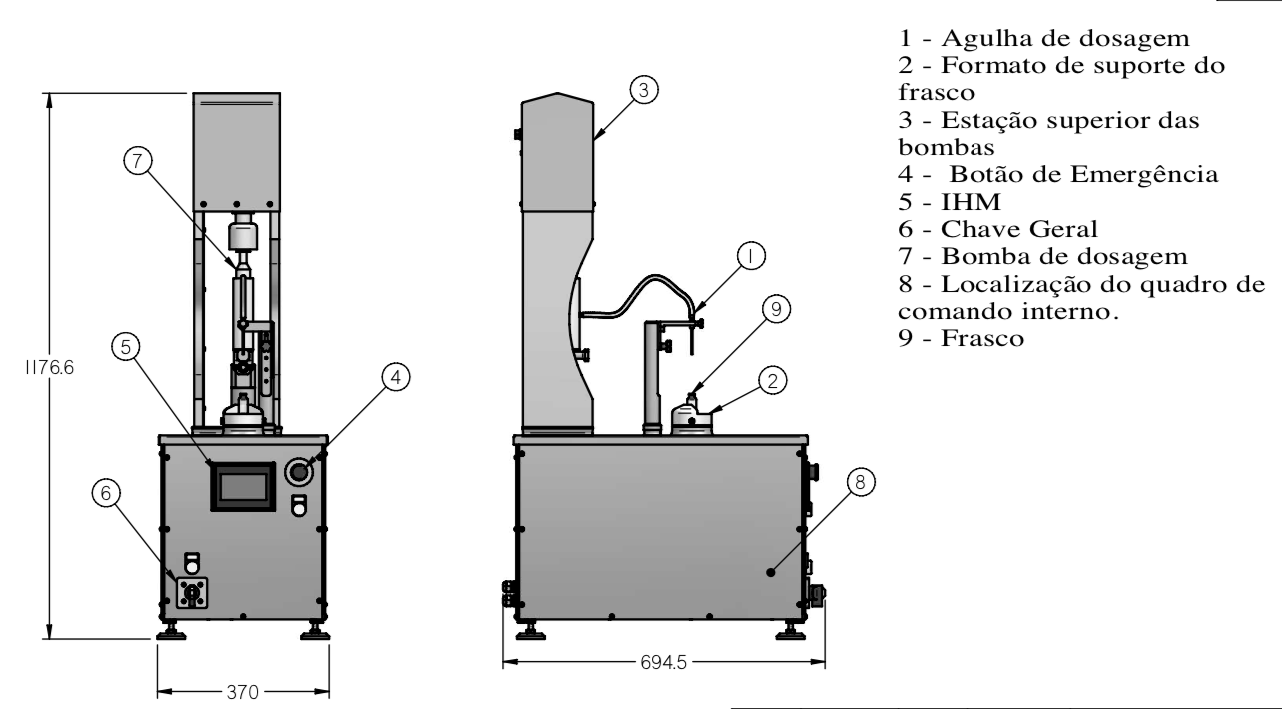

Semi-automatic Filler with Peristaltic Pump or Rotary Piston - DBP 1200

Semi Automatic Filling Machine - DBP 1200

Equipment built in AISI 304 stainless steel with polished finish, light anodized naval aluminum and electropolished and certified 316L stainless steel, for the parts of the equipment that come into contact with the product to be filled.

Non-apparent mechanism built in carbon steel with epoxy paint and black oxidation.

Production capacity

The equipment has a maximum production capacity of 1200 pcs/h when used with a dosing syringe. Productivity is inversely proportional to the dosing volume, that is, the greater the volume, the lower the productivity.

Dosing System

Machine can be supplied with 1 (one) peristaltic pump.

The pump can be supplied with different metering capacities, at the customer's discretion.

Below we describe the technical characteristics of the recommended pump:

• Dosing capacity of 1400 ml/min;

• Dosage variation from 0.1ml to 10,000ml;

• Crushing through stainless steel rollers;

• Head with safety lock and interlock option;

• Hole for draining the lid in case of leakage;

• Maximum operating pressure: 2 Bar;

• Set Horn: 220V

• Rotation 239 RPM;

• Engine power: 0.37 kW;

• Foot pedal, 24VDC command.